Why should you always prefer using stainless steel fasteners?

Stainless steel is undoubtedly the most personally preferred fastener somewhere in the entire world, and understandably so! Stainless steel usually comes with a range of benefits that make it both special and reliable. Although the general term for corrosion-resistant steel alloys is indeed stainless steel, minor differences in alloy constituents can greatly alter the whole electrical and otherwise mechanical characteristics of that component. By knowing the benefits of using the stainless steel fasteners, you will learn very much about the total components you supply to your customers for the long term.

Though a lot has now been said on the best way to actually use fasteners, we will give you a helpful guide to somehow help you work around typical errors you can actually make when using fasteners and how you somehow can stop them. Stainless steel screw manufacturers are much reliable.

STAINLESS STEEL IS CORROSION-RESISTANCE

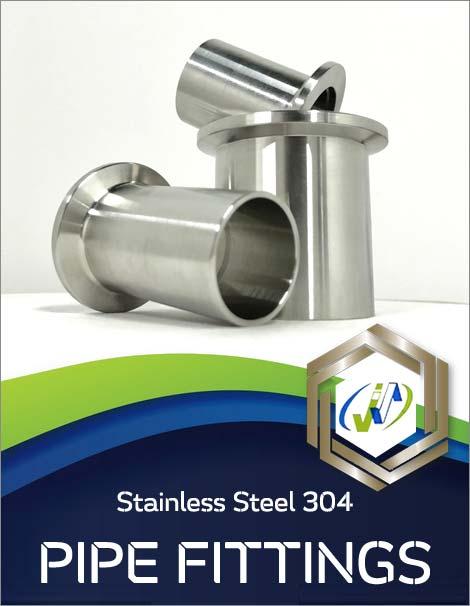

The fact that somehow stainless steel ss 304 pipe is indeed corrosion resistant is perhaps the best selling point for the basic material. Stainless steel already has slightly more than 10% of further chromium in its structure, causing a thin film of such chromium oxide to actually form on the whole outer surface of that material. This essentially stops further corrosion or deterioration from occurring following oxidation or otherwise exposure to some other corrosion-causing chemicals reactions. Stainless Steel 304 Pipe Fittings are also resistant once again to internal and otherwise external hydrogen friction, making it somehow the most sought even after commodity for the manufacture of fasteners. Stainless steel nut manufacturers are indeed very good.

STAINLESS STEEL FASTENERS are indeed self capable of repairing themselves

The thinner film of further chromium oxide mostly on the outer basic layer of the whole fastener actually uses oxidation to combat oxidation. Pretty smart, huh? In addition to further making the whole fastener corrosion resistant, perhaps the oxide coating also helps the fasteners to the self-repair. You can also contact stainless steel washers manufacturers. If a scratch or perhaps even dent or some other physical distortion affects the fastener, the bare alloy is already exposed to oxygen mostly on the affected component. Oxidation allows another layer of such chromium oxide to somehow form on this whole exposed layer, shielding it from further corrosion. Allen bolt manufacturers are also excellent.

Please note, however still, that although stainless steel ASTM A194 Grade 2H is rust resistant, it is certainly NOT at all corrosion resistant. though if the fastener itself is not adequately assembled, or if its proximity to oxygen is inadequate, or if, during the processing of the whole fastener, excess stainless steel ASTM a193 grade b7m particles remain on the elements, the risks of corrosion of the fasteners are considerably greater than those of the perfectly produced stainless steel fasteners. Flat washer manufacturers can easily be found on the internet.

SS FASTENERS usually have a LONGER LIFE

Just as the original material offers some excellent longevity, stainless steel ASTM A453 Grade 660 fasteners can therefore be used both underwater and otherwise in high temperatures. No other commodity will deliver such long-lasting benefits, or somehow at any cost, unless you really spend a lot on it! Although the initial cost of further Stainless Steel Eye Bolts can be quite high, they are indeed more cost-effective now in the longer run. You will certainly save more money over time, as direct replacement of further stainless steel fasteners just has to be performed once in a couple of decades. Find the best u bolt manufacturer in India.